Low Frequency Ultrasonic Transducers and Their ApplicationsTransducers and LeadsThe transducers consist of piezo-electric elements mounted in stainless steel cases. The elements are very tightly held on to the inside face of the case to provide highly efficient acoustic transmission. The transducer assembly is very robust and can withstand reasonably rough conditions as normally encountered under conditions of industrial usage. The high voltage excitation of the pulse generator causes the transducer to oscillate mechanically at its own natural frequency; this frequency depends on the size and stiffness of the whole transducer assembly. Different sizes of piezoelectric elements and cases enable different pulse frequencies to be obtained. Each transducer is fitted with a cable socket to enable it to be detached from the cable and to allow cables of different length to be used. Short co-axial cables for connecting the transducers to the V-Meter are supplied with the instrument. Longer cables may be used when access to the areas to be tested is restricted. Although long cables reduce the size of both the transmitted pulse and the receiving signal, these are generally both of adequate magnitude for testing even when the cables are up to 25 ft. long. Cable lengths of up to 20 meters(approximately 60 feet) have been used successfully with the optional pre-amp( V-C-4896 ). Note: When using very long leads, try to prevent the two leads from coming into close contact with each other when the transit time measurement is being taken. It is possible for the receiver lead to pick up unwanted signals from the transmitter lead resulting in an incorrect display of transit time. Such incorrect displays are readily detected by their instability and may be corrected by simply separating the leads.

Types of Transducers

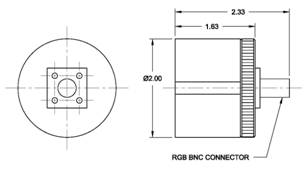

24

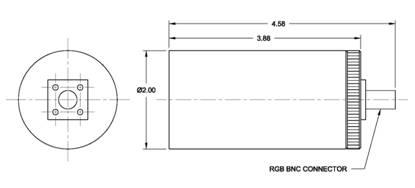

kHz Transducer

:

Used for larger (softball

sized) aggregates. Range is up to 16 feet without Pre-Amp.

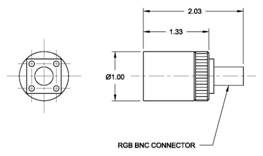

54

kHz

Transducer:

Most commonly used

transducer. Used for 12mm (½ inch) diameter aggregates. Range is up to

16 feet without

Pre-Amp.

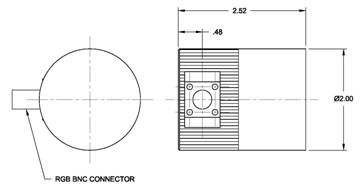

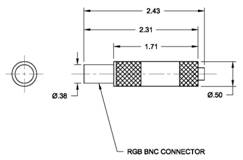

150 k Hz Transducer: Used for sand sized aggregate (mortar and ceramic). Range is up to 1 foot without Pre-Amp. A pre-amp is typically used in conjunction with these units.

500 kHz Transducer: Used for very small aggregate (ceramic and glass). Range is up to 1 foot without Pre-Amp. A pre-amp is typically used in conjunction with these units.

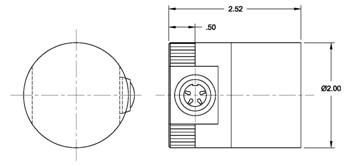

ShearWaveTransducer:

Used for finding

non-homogenous conditions of a surface. Space the transducers 1 foot

apart with

the lines facing each other.

No

Pre-Amp

required. Use of the shear wave transducers is

limited to indirect mode, i.e. each transducers needs to

be on the same surface of the material under test.

The flat edge of the transducer denotes the

orientation of the internal crystal.

These edges need to facing each other for

proper operation.

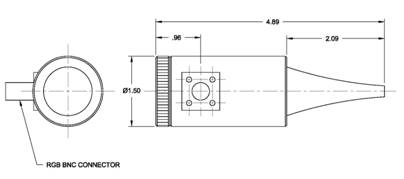

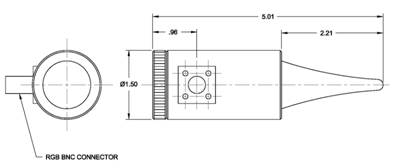

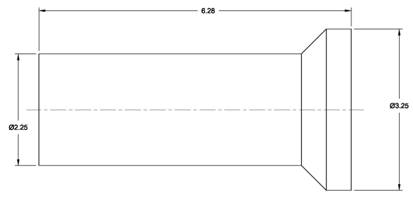

Exponential

Transducer:

Used for testing

samples with non-flat surfaces on either side. Range is 1 foot with

Pre-Amp. They were developed for either very rough

surfaces or to test specimens where a

standard size transducer does not fit.

A pre-amp is typically used in conjunction

with these units.

ExponentialTransducer Transmitter

Underwater

Transducer:

Used for a

substrate with softball sized aggregates that is submerged underwater.

Range is

16 feet without Pre-Amp, however a pre-amp is built into the recieving

unit.

Underwater Transmitters and Underwater Receivers are sold seperately.

Based

on the above descriptions, the user should be aware that using the

wrong

transducer for an application can lead to misleading results. If a low

frequency transducer (24 kHz for example) is used where the aggregate

being

tested is of a finer grade, the V-Meter could claim that there are no

issues

with the substrate when there could be. Similarly, if a high frequency

transducer (150 or 500 kHz) is used where the aggregate is too large,

the

V-Meter may claim that there are issues in the substrate when there

might not

be.

|